We specialise in vehicle diagnostics and training technicians to the high standards required to diagnose modern vehicle systems. We also tune vehicles to the exacting standards expected in the world of GT racing alongside Buddy Racing. We have teamed up with GotBoost to provide real time diagnostic and tuning solutions using a Mainline 2WD Chassis Dyno. We diagnose the faults other garages can not fix. We are truely Investors In petrol

Tuesday, 30 November 2010

The heat is on........

At this point he asked for a second opinion. This is where I enter the equation. The garage had asked me if I had seen this sort of fault before. Many times I explained, so they wanted to know the cause. Many things I explained. So armed with a list of possible causes and a warning to make sure the cause was found and not the effects.

They could find nothing wrong, and asked if I could give it the one over. When I arrived the front end was off the car, they had been checking the cam timing! (a much quicker method would of been manifold vacuum I explained. Noting the car has a map sensor I said just take a look at the live data. Key on engine off it should read 1000mbar and at idle 300mbar. If these are your readings then its a sure bet the cam timing is ok. So KOEO it was 1000mbar at idle it was 1000mar. BINGO! map sensor error staring you right in the face.

A new sensor was ordered up after testing with a scope and the cause of the fuelling problem sorted. This could lead to erroneous codes for O2 sensors and miss-diagnosis.

Next day and I am asked back the car is now back together so a test drive is possible.

The symptoms are the same as before and the fault codes remain O2 bank1 sensor 1&2.

After the test drive we put it on the ramp to check the O2 sensors and the exhaust was glowing red! Now the O2 sensors need to be 350 degrees to work but this was sensor heating in the extreme. I quick scope of the front sensor show a constant 850mvolts even when the injectors were switched off on overrun. Swapping the rear to the front restored normal operation of the fuel trims and the car was transformed. Two new sensors were fitted and the car returned to its owner. Who was less than pleased that whilst the previous garages had found the effect, O2 sensor failure, the cause had been the MAP sensor failure resulting in miss fuelling and damage to the O2 sensors and catalyst.

Saturday, 30 October 2010

Mondeo Madness

This car is an example of a 1994 BTCC Ford Mondeo, the engine had been away for a freshen up.

This car is an example of a 1994 BTCC Ford Mondeo, the engine had been away for a freshen up.When it was re-installed it would not start.

The wiring is in poor condition, this is in part due to the nature of beast. It was never intended to be racing over a decade later. Many of the components are repeatedly removed checked and replaced. This places a great deal of stress on wiring looms and connectors.

The historic nature of this car means it has to look as did when it competed in the BTCC, any changes must be under the surface. The coil is powered by two ignition amplifiers that are very sensitive to voltage spikes.

So this was the first place to check. No switch during cranking, bad news. A quick check of the injectors also showed no switch, so the fault could be crank or cam sensors.

They need to be in sync, with the cam 40 degrees before TDC cylinder 1.

A quick scope of the sensors shows both outputs are good, however the cam sensor is positioned too close to TDC. The expected position id the cursor 1 in the picture.

How is this worked out?

The time for 1 rev is calculated from the scope trace then divided by 360. This then gives the time in ms for 1 degree. 40 degrees is 45.3ms.

Simples.

Monday, 30 August 2010

Fore!

Fore!

I am often asked to check or to diagnose faults after another workshop has diagnosed the vehicle. This is sometimes at the request of the vehicle owner or the workshop.

A second opinion is sometimes sort if the repairs are costly bizarre or if the workshop can't make head nor tail of the data presented.

This Golf had a running fault which was diagnosed as the Air Mass Meter. A new unit was fitted the codes cleared and the vehicle given back to the owner.

The malfunction indicator lamp or MIL was no longer illuminated, however the car felt flat and was using an alarming amount of petrol.

The EPC warning light would illuminate above 4000rpm and extinguish once the rev's dropped.

The garage agreed to look at the car for no extra charge but could not determine what was wrong, the fault code or DTC was for a short to positive at the air mass meter. They could find no such fault.

I was asked to look at the vehicle, I took it for a test drive observing data driving style and the performance or lack of it.

Using the VCDS software on the laptop I was able to retrieve all the fault codes stored.

P1145 Mass Air Flow Sensor Short to Positive

P1141 Load calculation cross check : implausible value

The next step is to establish what is the data telling us, using the graphing function of the VCDS software.

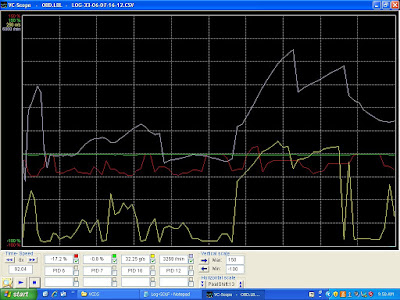

The air mass output (yellow trace) looks to mirror the engine speed (white Trace). The short term fuel trim (red trace) is negative during most of the data shown. the Long term fuel trim (green trace) is not showing much as the codes have just been cleared. This re-sets the long term fuel trim. I use this technique as the short term trim is for a short period of time is now reporting total fuelling adjustment.

From this we can establish that the engine is receiving too much fuel. This now makes sense, the P1141 code suggests that the load calculation does not agree with the data stored in the PCM look up tables.

How is load calculated? It depends on the system fitted to the vehicle, but typically it is the Throttle position, Manifold vacuum, engine speed, and air mass sensors that are used.

So the two codes are linked by the air mass, but it is a new unit. It couldn't be faulty could it?

By scoping the sensor we can eliminate the short to ground, the output looked good, no shorting out but the EPC light still illuminates.

I checked with the the vehicle owner and a non OE air mass has been fitted. There are two different types for this variant of the Golf, does the local motor know this?

I checked with the the vehicle owner and a non OE air mass has been fitted. There are two different types for this variant of the Golf, does the local motor know this?

A new air mass sensor from Volkswagen was ordered, fitted and after a successful test drive the codes cleared and the vehicle returned to the owner.

So the warning here is modern engine management systems require precise inputs from the various sensors a variation as small as 0.2V will cause running problems, fault codes and legislative failures.

Monday, 9 August 2010

Braking News

The 1st code lost communication with the transmission control module. The car is a manual but the 2nd hand control unit is from an automatic.

The clamping force code relates to the method of detecting when the brakes are fully applied. The motor runs until the control current reaches around 15 amps this is the stop signal to the control unit. If 15 amps is not achieved within around 20-30 seconds the motor stops and the code is flagged.

This suggests that the motor is turning but the caliper is not clamping the disc. A rubber drive belt is used to transmit the torque from the motor to a gear of about 50:1 ratio. Could this be snapped. Could it be a wiring fault still? Is the caliper motor of the correct resistance. How can we quickly check?

In measuring value blocks 003 the control current is displayed.

The left hand caliper is drawing 5.852 amps.

Using ohms law we can calculate the resistance of the circuit 12/5.9 = 2.05 ohms.This is within the expected range, but why does it not clamp the disc.

Wednesday, 4 August 2010

Mercedes ML not so well

Tuesday, 27 July 2010

Up's and down's of an electric window

The reason the this Peugeot was booked in was a simple electric window fault.

Another garage had tried to find the fault but gave up. As the window would go down but not up they powered the motor from a 12v battery to send the window back up then disconnected the motor. This way the window could not be left stuck down.

As always it is the approach that is most important with any diagnostic job.

We always question the customer, this way we know what previous repairs have been carried out, thus the repair history.

In this case this proved very useful as we now know the motor works, even though it appears not to work at all.

Next we look at what does and doesn't work in this case the window can be controlled from the drivers door as well as the passenger door. So with the motor reconnected does it go down from both switches. Yes.

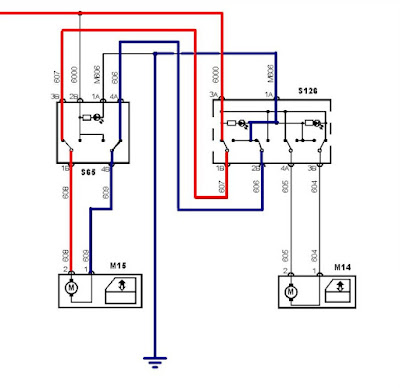

I am left with two options I have colored these in Red and Blue, Red the power supply for the motor and Blue earth in the up direction.To prove which is at fault I need to prove a loss of continuity between the passenger window switch and the drivers switch.

Most people would use a multi-meter set to ohms or the diode test position. We prefer to use current measurement for this test as it is dynamic. That is to say the circuit is in use. We needed to test between terminal 1b and 3b using the meter as the wires as the amp setting gives the meter very little resistance. Then 4a and 2b.

Knowing this before going to the car and testing reduces diagnostic time. Understanding the circuit means it can be tested quickly. It may take a few minutes before you pick up the meter but it can save hours.

In this case the wire between 4a and 2b was proved to be open circuit. This method proves the diagnosis as with the meter set to amps in place the window worked in both directions from both switches. The task of finding location of the broken wire is more difficult but knowing it was makes running another wire the quicker solution.

Thursday, 15 July 2010

Pugilistic Pug

The high priority job was enable the engine to stop on the key.

This is a safety critical repair, the first task was to get the engine started, the battery was completely discharged. A sure sign of the trouble ahead.

Once the engine started with a booster pack, you could remove the key and the thing kept running until you switched the lights on then off!

I fitted a replacement battery after cleaning all traces of electrolyte from the battery tray and surrounding areas. This restored the key to normal operation, but the side lights refused to switch off, plus the brake lights were on permanently.

The culprit, the brake switch had become dislodged. With the switch re-fitted and correctly adjusted we now had working brake lights, however the side lights came on every time the brakes were applied. I was beginning to think this was some sort of joke, but this is normally a simple case of incorrect filament lamps being fitted. Sure enough one of the brake light lamps was a single filament instead of a double filament, this back feeds the side light circuit putting the side lights on whenever the brake pedal is pressed.

The list of jobs was slowly reducing, but now I had to sort the passenger electric window. More on this next time.

Tuesday, 1 June 2010

Blinded by the light

Simple enough at first glance. (You can read more about the fault in an earlier post).

It turned out to be the side light/brake light that was inoperative.

I checked the lamp visually it appeared fine, so I measured it's resistance it showed 0.6 ohms.

This is the bit that got me thinking..............is that right? I compared it with the working side light and it too had a resistance of 0.6 ohms. So it is correct. Or is it?

These cars and many newer vehicles have done away with many of the fuses and use the ECU's to monitor faults, if any faults are detected it simply switches off the outputs. Then a warning is displayed in the dash panel. The joys of vehicle networks.

I set about some calculations to find out if the measured resistance was correct.

I knew the bulb rating 21W 12V therefore I could work out the current flow.

P= I x V

I =P/V = 21/12 = 1.75 Amps

Ohms law states I = V/R

R = V/I = 12/1.75 = 6.9 Ohms

So why was the resistance of the lamp filament so wrong?

Lamps convert heat into light, heating a conductor will increase its resistance. A lamp will show around 1/10th of its operating resistance in a "cold" measurement.

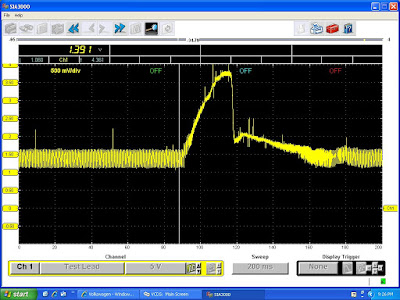

This can be clearly seen in the scope trace above, this was taken after I repaired a high circuit resistance in the wiring to the lamp. (the cause of the lamp failure warning you can read about in an earlier post).

Notice the "cold" resistance is much lower than the "hot" resistance seen as a high current 11 Amps falling to the operating current of 2 Amps. Notice how the Body ECU warms the filament with a short burst of current before switching the lamp on this stops current spikes and prolongs filament life.

Noble part 2

This car has proved difficult to diagnose, an intermittent miss fire, normally under load had proved elusive. Weather conditions, lack of rolling road time, along with fixing other basic problems had turned this into a bit of a saga.

Having checked the inputs/outputs of the ECU, everything appeared fine. However the car would occasionally cut out. Once this happened it would re-start and perform without fault for ever decreasing amounts of time. The ECU was inspected and tested and was found to be ok.I turned my attention to the coils, these showed good current ramping (below), but it was during these tests the car cut out. The output just vanished.

This means the ECU has stopped grounding the coils, but why? Could it still be an ECU fault?

I decided to investigate further, a check with the local Ford parts department proved fruitful.

The coils have been super seeded.

We tried a new coil to see if there is any noticeable difference. The current trace (above) shows the subtle but measurable difference. A further 5 coils were ordered and the car returned to the rollers. We now had closer to the rated output and no miss fires!

Monday, 24 May 2010

Have you seen the light?

A Golf MK V has a side light/brake light failure, however the local garage and the main agent have come to an expensive conclusion. It must be the body system interface. This computer controls many of the body and lighting functions on the vehicle. Replacement is costly not just the parts but the time plugged into the dealer diagnostic interface "coding" the unit.

This vehicle has few relays and even fewer fuses. The circuit at fault has no apparent circuit protection. If a fault is detected by the body interface it simply turns off the supply.

This in turn puts a fault light and message on the multi function display on the dash.

This vehicle had no such message or warning light. No fault codes were found in the body system interface. The lamp had been checked and passed both visual and resistance checks.

Yet when the side lights were switched on, or the brake pedal depressed the lamp failed to light.

The previous repair shops had checked for voltage at the lamp, and the output of the BSI.

No voltage means no output from the BSI, with no codes the garages had assumed this meant an ecu fault.

Is this diagnosis correct?

The main agent was unsure and requested we checked the system. The BSI checks for faults two ways termed hot and cold monitoring.

Cold monitors run every time the ign is switched on, hot monitors run while the circuit is in use.

A quick check with the scope showed the cold monitor was indeed running. So why was there no output, and if the was a circuit fault why no code? Or warning light/message?

You will often hear me banging my drum about Voltage Drop testing, however this can only be carried out with the circuit in use. ( Dynamic Testing) in this case this is not possible, so we tested using resistance checks, first continuity to ground (short to earth) then short to live with no fault error message we expected these simple checks to be fruitless. So it proved.

However the resistance between the BSi and the lamp showed 57 Ohms. Bingo this test was then repeated along the loom until the section at fault was identified. A loom connection proved to be the culprit showing signs of corrosion, and once cleaned and protected from further water Ingres normal operation was restored. It appears the fault is outside the fault code parameters but within the fault limit. This results in no output and no warning light/message on the multi function display. This has to be the worse case for the technician.

Tuesday, 27 April 2010

ABS Diagnosis

These were fitted and the fault remained!

The garage checked for codes but as the ABS light was not illuminated they were not surprised to find a clean bill of health. No codes found.

I was asked to check the braking system and report my findings.

A quick test drive proved the ABS to be operating, but not when you expected.

In cases like this I like to remove the ABS fuse to disable the system, then perform a road test. This careful road test, remembering the ABS will not operate can prove if it is an ABS control or operating fault, or a mechanical fault in the braking system.

In this case the car now performed faultlessly. Proving an ABS fault.

But without fault codes how can it be diagnosed quickly?

Start with a visual check, and sure enough the reason was clear to see a cracked reluctor ring.

Not easy to spot, but easy to see with the scope.

Friday, 26 March 2010

Current Affairs

More often than not the data given for components is the resistance value.

I have a saying "resistance is futile".

This is because you need to disconnect any component to measure its resistance, this is a problem. We need to test under the conditions that the fault occurs.

So why is it, resistance is the only information given to technicians to test components?

The resistance is important information, using ohms law we can calculate the current in the circuit and test under loaded conditions using an amps clamp.

These inductive clamps can be used without interrupting the circuit so testing takes place under the same conditions as the fault occurs.

E.G. A typical petrol injector has a resistance of 14-16 Ohms.

The supply voltage is 12-14 Volts

Therefore the current draw should be in the range 1 - 0.75 Amps.

Tuesday, 16 February 2010

Compression Test

Thursday, 14 January 2010

Tour de Corsa

However using some quick serial data tests showed normal rail pressure, pressure regulation duty cycle and using the scope the pressure build and decay all looked to be with normal limits.

This was a good example of an all approaches diagnosis.

Good serial data, backed up by live scope readings, however the vehicle still had a miss fire once started from cold or after touching the accelerator if started from warm.

A quick look at exhaust manifold temps using an infra-red thermometer showed cylinder 4 to be the culprit. Suspecting poor servicing in the past an engine flush and service restored normal operation.

Much cheaper than a high pressure fuel pump!