A local garage connected us about this a few days ago.

The owner complained of ticking noise from under the vehicle, and it had jumped from 4th to 1st gear. Now it will not drive but will start.

They checked for codes and P0300 was logged, random miss fire.

The garage suspected a fuel fault and checked fuel delivery, they discovered a very dirty fuel filter which was replaced. They then cleared the codes and tested the vehicle, not much better and now they had miss fire cyl 1, 2, & 3. So they checked the condition of the spark plugs, these were in poor condition so a new set was fitted.

However this had not improved the situation, they believed the dirty fuel (it was black coming out of the filter) had damaged the injectors. So they asked if we could take a look.

In cases such as these, it is tempting to carry on where the other garage left off. But this could be a mistake we always start with a few questions of the customer. (In this case the garage) Followed by a test drive to witness the fault and gather data. Then we test to prove what it is or in many cases what it isn't.

The test drive was brief the ML could hardly move itself off the forecourt.

Upon snapping open the throttle both O2 sensors went lean. If you coaxed the thing to rev they stayed lean. I normally perform a snap throttle acceleration of the engine to put a bit of strain on the ignition and fuelling systems.

These Mercedes prevent a full test by limiting the revs of the engine when the vehicle is stationary.

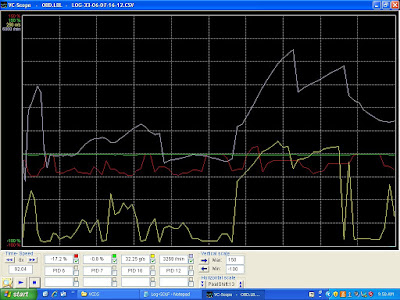

So having captured some live data, it was time to evaluate this data. The lean signal from both O2 sensors under snap acceleration and fast idle pointed towards a problem when the fuel demand increased. This was common to both banks so fuel pump testing became the obvious first test. We perform a number of different tests for fuel pumps. However we prefer not to break into any system so non intrusive amps clamp testing of the pump always features high on the list of preferred fuel pump tests.

We check the pump electrically and physically in one quick and easy test, and by analysing the waveform we can see bad pump sectors, freewheeling rotors and slow rotation.

In this case the return and fuel pressure regulator are part of the filter assembly, the fuel pipe is braided and prevents clamping to increase pressure to observe how the waveform reacts.

But satisfied the pumping element was OK, we tested the pressure at the rail and measured the flow rate checking for air in the fuel.

All was within specification, which ruled out a supply problem. Could the injectors be blocked by the contaminated fuel? They only way to find out is to remove and test on a flow bench. We can perform this test but as it requires dismantling of the fuel system, we decided to rule out all other suspects first.

What else could effect the fuelling on both banks?

Coolant temp sensor, air temp, air mass meter all sprung to mind.

The live data capture showed expected readings for coolant and air temp, the air mass is a much harder parameter to analyse a good rule of thumb is the idle reading in g/s the ML showed 8g/s at idle. I expect 10-14g/s from a 3.2L V6, so could we have an under estimating AMM. The resultant weak mixture the cause of the random miss fires, fuel trim is in the 30% range on both bank at fast idle.

A quick but not always accurate diagnosis can be made by disconnecting the AMM and trying the test drive again, if things improve then it certainly looks like the problem is in the remit of the AMM but doesn't mean the AMM itself has failed.

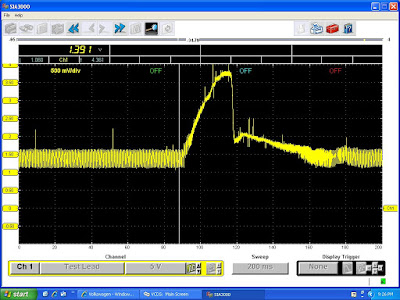

Testing with an oscilloscope is a much better bet, normally we look for at least 4V as the throttle is snapped open and 4.5V as it revs up to max rpm.

The ML has restricted rpm's when stationary but the trace below shows only 2.77V

A new AMM cured the problem here is the difference in scope trace the new AMM hit 3.2V stationary. The new AMM now read 12g/s at idle in live data.

This is a simple inductive crank sensor from the front pulley. There was a signal, however it was different from the expected signal. We suspected the crank sensor was the culprit. A quick resistance check showed a normal 0.8K ohms, this is why an oscilloscope is essential, if we had just used a meter, we would have an AC frequency and the correct resistance readings. This would then suggest a fault with the EDIS module.

This is a simple inductive crank sensor from the front pulley. There was a signal, however it was different from the expected signal. We suspected the crank sensor was the culprit. A quick resistance check showed a normal 0.8K ohms, this is why an oscilloscope is essential, if we had just used a meter, we would have an AC frequency and the correct resistance readings. This would then suggest a fault with the EDIS module.

I checked with the the vehicle owner and a non OE air mass has been fitted. There are two different types for this variant of the Golf, does the local motor know this?

I checked with the the vehicle owner and a non OE air mass has been fitted. There are two different types for this variant of the Golf, does the local motor know this?